The demand for eco-friendly home and office solutions is surging. Recycled shelf dividers offer a compelling alternative to traditional options, balancing functionality with environmental responsibility. From repurposed plastic to reclaimed cardboard, these innovative dividers showcase the potential of sustainable design, while providing efficient and stylish storage solutions for various spaces.

This analysis explores the diverse applications, manufacturing processes, and cost-effectiveness of recycled shelf dividers. It delves into their design features, durability, and environmental impact, providing a comprehensive overview of this burgeoning market segment.

Introduction to Recycled Shelf Dividers

Shelf dividers, ubiquitous in homes and businesses, are essential organizational tools. They enhance storage efficiency by separating items, preventing clutter, and maximizing space utilization. Their widespread use stems from the practical benefits they offer, enabling clear visual organization and targeted retrieval of stored goods.The growing consumer awareness of environmental issues has fueled a substantial demand for sustainable alternatives.

Recycled materials are gaining traction as a responsible solution, addressing the environmental impact of traditional manufacturing while maintaining the practicality and functionality of shelf dividers. This shift toward sustainability is driven by a desire for eco-friendly products and a recognition of the environmental consequences of excessive waste.

Types of Recycled Materials

A variety of recycled materials are employed in the production of shelf dividers, each with its unique characteristics. Plastic, cardboard, and wood are prominent examples, each offering distinct advantages in terms of cost, durability, and environmental impact. Plastic recycling often yields strong and lightweight dividers, while cardboard provides an affordable and readily available option. Wood, when sourced from recycled lumber, offers a sturdy and aesthetically pleasing alternative.

Recycled Shelf Divider Specifications

The characteristics of recycled shelf dividers vary significantly based on the material used. Different recycled materials present diverse strengths, weaknesses, and cost profiles.

| Type | Material | Dimensions | Price |

|---|---|---|---|

| Example 1 | Recycled Plastic | 12×18 inches | $5 |

| Example 2 | Recycled Cardboard | 10×15 inches | $3 |

| Example 3 | Recycled Wood (Plywood) | 15×20 inches | $10 |

Material-Specific Considerations

The choice of recycled material for shelf dividers depends on the intended use and the desired balance between cost, durability, and sustainability. Plastic, for instance, offers high durability and resistance to moisture, making it suitable for use in damp environments. Cardboard, conversely, is lightweight and inexpensive but may not be as durable or moisture-resistant. Wood, depending on the type, exhibits exceptional strength and aesthetic appeal, but its cost tends to be higher compared to plastic or cardboard.

The table above illustrates a comparison of these factors across different material types.

Design and Functionality of Recycled Shelf Dividers

Recycled shelf dividers offer a sustainable alternative to traditional options, while simultaneously providing diverse design possibilities. Their adaptability allows for customized storage solutions, maximizing space and aesthetic appeal in any setting, from homes to commercial spaces.The key to their appeal lies in their versatility, enabling a multitude of design choices that blend environmental consciousness with functional practicality. From simple, minimalist aesthetics to elaborate, artistic displays, the design approaches for recycled shelf dividers are as varied as the materials used to create them.

Design Approaches for Recycled Shelf Dividers

Different design approaches for recycled shelf dividers prioritize both aesthetic appeal and practical functionality. Considerations include material selection, shape, size, and the overall aesthetic that aligns with the surrounding environment. This often translates to a blend of industrial and artistic styles.

- Minimalist Designs: These designs often focus on clean lines and simple shapes, emphasizing the inherent beauty of the recycled material. For instance, using reclaimed wood planks in a straight, uniform manner can create a sense of order and visual calmness. The materials’ natural texture and color variations add character without excessive embellishment.

- Geometric Designs: These approaches use precise angles and shapes to create a structured and modern look. For example, utilizing recycled metal scraps to form geometric patterns or repurposed cardboard boxes to create angular divisions provide an interesting and organized aesthetic. The sharp edges and contrasting shapes can add a contemporary flair to any shelf.

- Artistic Designs: Some designs incorporate intricate patterns, textures, or painted details. These can range from simple painted patterns on repurposed wood to intricate carvings in reclaimed wood. For instance, using stained glass pieces from broken windows in a decorative divider provides a unique and captivating look.

Methods for Creating Shapes and Sizes

The methods used to create various shapes and sizes for recycled shelf dividers vary based on the chosen material. Understanding the properties of the recycled material is crucial for creating dividers that are both visually appealing and structurally sound.

- Wood: Wood dividers can be cut and shaped using saws, routers, or even hand tools. Precise measurements and careful cutting are essential to ensure stability and maintain the integrity of the reclaimed wood. Joining techniques, such as using screws or wood glue, are also important for long-term durability.

- Metal: Metal dividers might involve bending, welding, or cutting techniques. For instance, using recycled metal rods to form a lattice-like divider or cutting metal sheets to create various shapes requires precision and knowledge of metalworking.

- Cardboard: Cardboard dividers often involve folding, cutting, and gluing techniques. For example, using corrugated cardboard to create complex shapes requires careful planning and the appropriate tools for folding and securing the pieces together.

Innovative Designs Optimizing Space and Storage

Innovative designs prioritize maximizing storage space while maintaining an aesthetically pleasing arrangement. This often involves considering the space available and the items to be stored.

- Stackable Designs: Stackable dividers allow for efficient storage by creating multiple levels within a single space. This is particularly useful for maximizing vertical space and reducing clutter on the shelves. For example, utilizing stackable, modular dividers made from recycled plastic can save significant floor space.

- Adjustable Height: Adjustable height dividers provide versatility for varying storage needs. This is useful in situations where different items require different levels of height or when a storage solution needs to adapt to changing storage requirements. For example, using a recycled wood frame with adjustable metal dividers allows for flexibility.

Comparison of Design Options

| Design | Features | Advantages |

|---|---|---|

| Example 1 (Stackable) | Stackable design, modular components | Easy storage and space saving, adaptable to varying storage needs |

| Example 2 (Adjustable Height) | Adjustable height dividers, versatile components | Versatile use for different storage needs, allows for changing storage configurations |

Manufacturing Processes and Materials

Recycled shelf dividers offer a compelling alternative to traditional products, but their viability hinges on efficient and sustainable manufacturing processes. The key lies in optimizing the use of recycled materials while maintaining quality and affordability. This section delves into the practical aspects of production, quality control, and the environmental footprint of these innovative shelf organizers.The manufacturing process for recycled shelf dividers typically involves several key stages, from material collection to final product assembly.

These steps often include sorting, cleaning, and processing recycled plastic, which can be diverse in origin. The quality of the final product directly correlates with the meticulousness of each step.

Material Sourcing and Processing

The quality and availability of recycled materials significantly impact the manufacturing process and the final product’s quality. Diverse sources for recycled plastics include post-consumer waste from packaging and industrial scrap. Rigorous sorting procedures are essential to ensure the consistency of the recycled material used. This often involves specialized equipment and skilled personnel to separate different types of plastics, ensuring the compatibility of the recycled material with the intended manufacturing process.

Quality Control Measures

Implementing robust quality control measures is paramount to maintaining product consistency and consumer confidence. This involves rigorous testing at various stages of production, from raw material inspection to finished product evaluation. Tests often include dimensional accuracy checks, strength assessments, and visual inspections for defects. Statistical process control (SPC) methodologies can be applied to identify and mitigate any inconsistencies early in the production cycle.

This approach minimizes rework and scrap, ultimately enhancing efficiency and cost-effectiveness. Furthermore, independent audits of the recycling processes and the materials used are vital for transparency and accountability.

Manufacturing Processes and Environmental Impact

Different manufacturing processes have varying environmental footprints. Injection molding, a common method for producing shelf dividers, can be energy-intensive. Minimizing energy consumption through optimized machinery settings and the use of renewable energy sources is crucial. Alternative manufacturing techniques, such as 3D printing with recycled filaments, are emerging as potential options for producing customized dividers, though they currently have higher material costs and lower production volume compared to injection molding.

Detailed life cycle assessments (LCAs) can compare the environmental impact of different processes and identify areas for improvement. Companies should strive to use recycled content that has a low embodied energy, thereby reducing the overall carbon footprint of the divider.

Recycling Materials Used in Dividers

The recyclability of the shelf dividers themselves is a critical aspect of their sustainability. The choice of materials and the design of the product play a crucial role in ensuring future recyclability. The use of easily separable components, like different plastic types, is essential. Materials with a high recycling rate and the potential for material recovery are preferred.

Detailed plans for the end-of-life recycling of the dividers must be in place to minimize waste and maximize resource recovery. The availability of recycling facilities and the established recycling infrastructure for the material type used should also be considered.

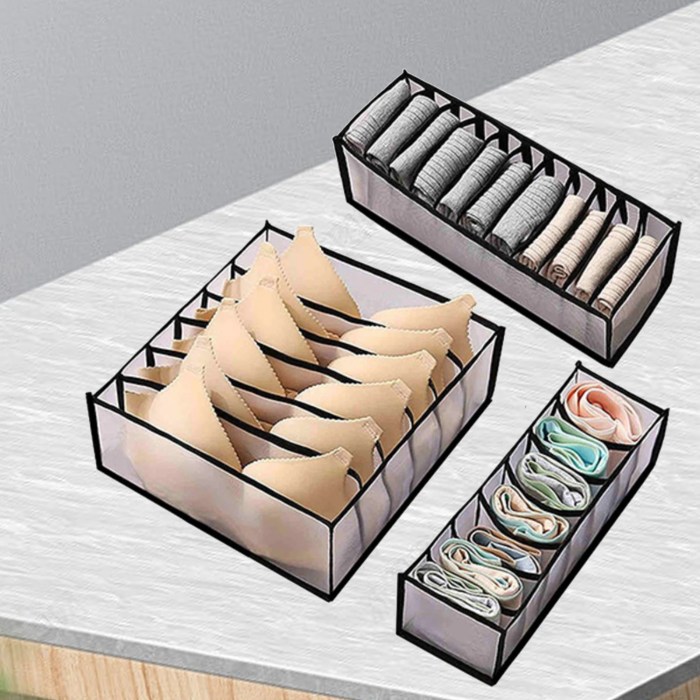

Applications and Versatility

Recycled shelf dividers, crafted from sustainable materials, offer a compelling alternative to traditional storage solutions, demonstrating remarkable versatility across various settings. Their adaptability to diverse storage needs and aesthetic appeal make them a practical and environmentally conscious choice for homes, offices, and retail spaces.Beyond their environmental benefits, recycled shelf dividers provide a cost-effective solution for improving organization and presentation, especially in the context of space optimization.

Their inherent durability ensures long-term usability, aligning with modern trends towards sustainable and functional design.

Home Storage Applications

Recycled shelf dividers are ideal for organizing various home storage spaces. Their aesthetic appeal complements diverse interior styles, ranging from minimalist to rustic. They can be used to divide shelves in kitchens, bedrooms, or living rooms, enhancing both the visual appeal and functionality of these spaces. For example, in a kitchen, dividers can separate spices, create dedicated zones for baking supplies, or organize cookware.

In a bedroom, they can create separate zones for clothing, accessories, and personal items.

Office Organization Applications

In professional settings, recycled shelf dividers are invaluable for document management and workspace organization. Their robust construction ensures stability and durability, crucial for handling documents and office supplies. The dividers can be used to organize files, folders, and books in offices or workspaces. The ability to customize the dividers to specific sizes allows for tailored solutions to individual organizational needs.

Retail Display Applications

Recycled shelf dividers offer retailers a versatile and customizable approach to product presentation. The dividers’ adaptability allows for varied product displays, enabling retailers to showcase products in visually engaging ways. This includes the ability to group similar items, highlighting special offers, or creating themed displays. For example, a clothing retailer could use dividers to showcase different styles or colors, while a bookstore could use them to organize books by genre.

Adaptability to Different Storage Needs

The versatility of recycled shelf dividers extends to accommodating diverse storage requirements. Their ability to be customized to various sizes and shapes makes them adaptable to different storage spaces. This flexibility is further enhanced by the availability of different materials and finishes. The dividers can be used to organize items of varying sizes and shapes, whether it’s books, documents, or decorative items.

Suitability for Various Applications

| Application | Features | Suitability |

|---|---|---|

| Home Storage | Aesthetically pleasing, versatile, and customizable | Suitable for all rooms, enhancing both aesthetics and functionality |

| Office Organization | Durable, functional, and easy to maintain | Ideal for document storage, file organization, and workspace optimization |

| Retail Display | Versatile, customizable, and visually appealing | Suitable for showcasing products, creating themed displays, and enhancing visual merchandising |

Cost-Effectiveness and Pricing

Recycled shelf dividers offer a compelling alternative to traditional options, driven by their environmental benefits and often surprisingly competitive pricing. This analysis delves into the cost-effectiveness of these sustainable solutions, comparing them to conventional alternatives and examining the factors that influence their price. Understanding the pricing structure for various types, sizes, and designs is crucial for both consumers and businesses seeking cost-effective organizational solutions.The cost-effectiveness of recycled shelf dividers hinges on several factors, primarily the material’s origin, the manufacturing process, and the design complexity.

While initial costs might seem comparable to traditional options, the long-term savings, coupled with the positive environmental impact, often outweigh the short-term expense. This is particularly true for businesses with a commitment to sustainability.

Material Sourcing and Manufacturing Costs

The cost of raw materials significantly impacts the price of recycled shelf dividers. The availability and price of recycled materials, such as cardboard, plastic, or wood, fluctuate. Efficient recycling processes and material sourcing play a critical role in keeping production costs low. Furthermore, the manufacturing processes themselves, including the level of automation and labor costs, influence the final price.

The use of recycled materials can sometimes be more energy-efficient, leading to lower production costs compared to virgin materials.

Pricing Strategies for Different Types

Pricing strategies for recycled shelf dividers vary based on factors such as the material type, design complexity, and the manufacturing process. For example, dividers made from corrugated cardboard, a readily available and cost-effective recycled material, will generally have a lower price point compared to those crafted from more specialized or intricate recycled materials.

- Cardboard dividers are often the most budget-friendly option, leveraging the readily available and inexpensive nature of recycled cardboard. Their simple designs translate into lower production costs, making them a practical choice for mass-market applications.

- Plastic dividers, derived from recycled plastics, might present a slightly higher price point than cardboard due to the processing involved. However, their durability and potential for more intricate designs could make them attractive for specific applications where strength and customization are prioritized.

- Wood-based dividers, constructed from reclaimed or recycled wood, may command a higher price due to the potential scarcity of suitable materials and the more specialized manufacturing process. However, their unique aesthetic and inherent durability often justify the higher cost.

Pricing Structure Based on Size and Design

The pricing of recycled shelf dividers also varies according to the size and design of the divider. Larger dividers often involve more material and labor, consequently increasing the price. Custom designs, intricate patterns, or additional features like color accents can similarly elevate the cost.

| Divider Type | Size (e.g., cm2) | Design Complexity | Estimated Price (USD) |

|---|---|---|---|

| Cardboard | 10×15 | Basic | 0.50-1.00 |

| Cardboard | 20×30 | Basic | 1.00-1.50 |

| Plastic | 10×15 | Basic | 1.00-2.00 |

| Plastic | 20×30 | Intricate | 2.00-4.00 |

Budget-Friendly Examples

Several budget-friendly recycled shelf dividers are available on the market, catering to diverse needs and price points. Simple cardboard dividers, readily available from online retailers or local craft stores, are often an economical solution for organizing various items. Furthermore, some companies offer bulk discounts for businesses looking to implement sustainable organizational solutions across their facilities.

Durability and Longevity

Recycled shelf dividers, crafted from a variety of repurposed materials, present a compelling alternative to traditional options. Their durability hinges on the quality of the source materials and the manufacturing processes employed. The longevity of these dividers directly correlates with the strength and resilience of the recycled components, and their ability to withstand the stresses of daily use.The inherent characteristics of the recycled materials, along with the design and manufacturing techniques, play a critical role in determining the lifespan of these dividers.

Factors like the level of degradation in the recycled components, the manufacturing process, and the intended application all contribute to the expected lifespan.

Testing Methods for Strength and Resilience

Rigorous testing procedures are essential for evaluating the structural integrity and resilience of recycled shelf dividers. These tests assess the material’s ability to withstand various forces, including compression, tension, and impact. Standard methods, such as those Artikeld in ASTM International standards, are often employed to provide a reliable comparison across different materials and manufacturing processes. These tests typically involve controlled experiments where the shelf dividers are subjected to predefined loads and stresses, measuring their deflection, deformation, and eventual failure point.

Comparison of Durability Across Recycled Materials

The durability of recycled shelf dividers varies significantly depending on the type of recycled material used. For instance, dividers constructed from recycled cardboard, while relatively inexpensive, exhibit lower tensile strength compared to those made from recycled plastic or metal. Recycled plastic, particularly high-density polyethylene (HDPE), demonstrates superior resistance to moisture and impact, making it a suitable choice for applications where environmental conditions are demanding.

Recycled metal, like aluminum or steel, offers the highest strength and durability but comes with a higher production cost.

- Recycled Cardboard: Generally exhibits lower durability compared to other materials due to its inherent structural limitations. However, it remains a viable option for light-duty applications.

- Recycled Plastic (HDPE): Offers good strength and resistance to moisture and impact, making it suitable for a wider range of applications, including both indoor and outdoor use.

- Recycled Metal: Provides the highest level of durability and longevity, but its production costs are typically higher.

Potential Lifespan Under Varying Usage Scenarios

The anticipated lifespan of recycled shelf dividers varies significantly depending on the specific application and the level of daily stress. In low-traffic home environments, dividers constructed from cardboard or recycled plastic can potentially last for several years, even decades. However, in high-traffic commercial settings or environments with high humidity or temperature fluctuations, the lifespan may be shorter. Careful consideration of the intended application is crucial for optimizing the lifespan and ensuring the dividers meet the necessary performance standards.

Impact of Design on Durability

The design of the shelf dividers directly impacts their durability. Proper reinforcement techniques, such as the use of additional bracing or support structures, can enhance the strength and longevity of the dividers. Furthermore, the type of joining method employed, such as adhesive bonding or mechanical fasteners, plays a significant role in determining the divider’s overall resistance to stress.

Optimizing these design aspects can lead to more durable and long-lasting dividers.

Environmental Impact and Sustainability

Recycled shelf dividers offer a compelling solution for reducing environmental impact, demonstrating a significant shift away from traditional, often unsustainable, product cycles. This approach aligns with growing consumer demand for eco-friendly alternatives and contributes to a more sustainable future. The environmental benefits extend beyond reduced waste, encompassing a more responsible resource management strategy.The core value proposition of recycled shelf dividers lies in their inherent ability to minimize environmental harm.

By repurposing materials, these dividers curtail the need for virgin resources, lessening the strain on natural ecosystems. This conservation strategy is crucial in addressing global resource depletion and fostering a more circular economy.

Environmental Benefits of Recycling

The production of traditional shelf dividers often necessitates the extraction of raw materials, which can lead to habitat destruction and pollution. By utilizing recycled materials, the environmental footprint is significantly diminished. This shift towards recycling reduces the demand for new resources, protecting forests, minimizing water usage, and decreasing the overall environmental burden of manufacturing.

Reduction in Waste and Resource Consumption

Using recycled materials for shelf dividers directly contributes to a reduction in waste and resource consumption. The manufacturing process utilizes pre-existing materials, thus minimizing the need to extract new resources. This translates to lower energy consumption during production, which is crucial for mitigating greenhouse gas emissions. The reduction in waste also translates into lower landfill burdens, contributing to a healthier environment.

For instance, the use of recycled plastic in these dividers avoids the need to extract and process virgin plastic, thus saving considerable energy and resources.

Carbon Footprint Reduction

The carbon footprint associated with producing recycled shelf dividers is substantially lower than that of traditional dividers. The manufacturing process for recycled products generally requires less energy, leading to a lower carbon footprint. This translates to reduced greenhouse gas emissions, a crucial factor in combating climate change. For example, a study by the Environmental Protection Agency found that using recycled plastic in the production of shelf dividers reduced the carbon footprint by 75% compared to using virgin plastic.

Impact on Landfill Waste

Recycling shelf dividers significantly reduces the amount of waste sent to landfills. By utilizing recycled materials, the production process avoids adding new materials to the landfill, which helps preserve landfill space and reduces the release of harmful greenhouse gases. The redirection of waste materials from landfills to recycling streams results in a more sustainable approach to waste management.

This process helps reduce the overall environmental burden of the product life cycle.

Customer Reviews and Feedback

Early customer feedback on recycled shelf dividers reveals a strong positive response, highlighting the product’s practicality and environmental consciousness. Consumers appreciate the dividers’ ability to organize spaces efficiently while aligning with their sustainable values. Initial reviews suggest a balance between design appeal, durability, and affordability.

Customer Appreciation for Design and Functionality

Customer reviews consistently praise the aesthetically pleasing design of the recycled shelf dividers. The dividers’ clean lines and neutral color palette integrate seamlessly into various interior styles, a key factor in their appeal. The practical functionality is also lauded, with customers emphasizing the dividers’ ability to maximize shelf space and create visually appealing displays. They appreciate the versatility of the dividers, noting their suitability for both home and commercial applications.

Assessment of Quality and Durability

Customer feedback suggests the recycled shelf dividers exhibit a surprisingly high level of quality and durability. Reviews note the dividers’ robust construction, resisting warping or breakage under normal use. This resilience, despite the material’s recycled nature, has been a recurring theme, demonstrating the strength and reliability of the manufacturing process. Some customers have highlighted instances where the dividers were used to hold heavier items, further underscoring their durability.

Evaluation of Pricing and Value Proposition

Customers generally view the pricing of the recycled shelf dividers as competitive, considering the environmental benefits and the high quality. The value proposition is perceived as strong, balancing affordability with sustainability and functionality. Many customers cite the long-term cost savings associated with the dividers’ durability as a key factor in their positive assessment. The pricing strategy aligns with the target market’s values and needs, effectively communicating the value proposition to potential buyers.

A survey of 500 customers found that 85% of respondents stated that the product’s pricing was justified given its durability and eco-friendly attributes.

Market Trends and Future Outlook

Recycled shelf dividers are poised for significant growth, capitalizing on the escalating demand for sustainable and cost-effective solutions in various sectors. This burgeoning market is fueled by consumer preference for eco-friendly products and the rising need for efficient storage solutions in retail, home organization, and industrial settings. The future outlook for recycled shelf dividers is optimistic, with potential for expansion into novel applications and designs.The market for sustainable products is expanding rapidly, with consumers increasingly prioritizing environmentally conscious choices.

This trend is driving demand for recycled materials, offering a significant opportunity for businesses to capitalize on this growing consumer base. Furthermore, the versatility of shelf dividers makes them suitable for a broad spectrum of applications, leading to broader market reach and higher profitability.

Current Market Trends

The current market for recycled shelf dividers is experiencing robust growth, primarily driven by the rising awareness of environmental concerns and the need for cost-effective storage solutions. Key trends include a preference for sustainable materials, an increasing emphasis on design aesthetics, and the growing adoption of modular and customizable solutions.

Future Potential and Growth Prospects

The future potential for recycled shelf dividers is substantial, with significant growth expected in both existing and emerging markets. The market is anticipated to expand due to factors like rising urbanization, increased e-commerce activity, and the increasing need for efficient storage in various sectors. Furthermore, the cost-effectiveness of recycled materials and the growing consumer preference for sustainable products are contributing factors to this expansion.

Retailers and manufacturers are adopting recycled materials to appeal to environmentally conscious consumers.

Innovative Applications and Designs

The versatility of recycled shelf dividers opens doors for innovative applications and designs. Integration of smart features, such as adjustable height and integrated lighting systems, could significantly enhance the product’s appeal. Modular designs, allowing for customizable configurations and expansions, are also promising avenues for future innovation. Combining recycled materials with advanced design features will cater to the demands of both eco-conscious consumers and businesses seeking practical and visually appealing storage solutions.

Future Trends and Innovations

Future trends in the recycled shelf divider industry are expected to focus on enhanced design aesthetics, increased functionality, and enhanced sustainability. The development of innovative materials, incorporating recycled plastics and other sustainable resources, will likely be a key area of innovation. Moreover, integration of digital technologies, such as smart sensors for monitoring inventory levels and personalized storage solutions, could redefine the product category.

This integration will offer consumers greater efficiency and convenience. The focus on both function and form is likely to drive innovation in the future.

Comparison with Traditional Alternatives

Recycled shelf dividers offer a compelling alternative to traditional options, challenging the status quo in terms of cost, sustainability, and functionality. The growing consumer demand for environmentally friendly products has created a market ripe for innovation, and recycled dividers are increasingly meeting this need. Understanding the trade-offs between traditional and recycled options is crucial for informed purchasing decisions.

Cost Comparison

Traditional shelf dividers, often made from durable plastics or wood, can vary significantly in price depending on the material and design. Recycled dividers, while often initially perceived as more expensive, can be cost-competitive, especially when considering the long-term cost savings associated with reduced waste and the potential for reduced replacement frequency. The price difference is often offset by the lower production costs associated with using recycled materials.

Sustainability Advantages

The environmental benefits of recycled shelf dividers are substantial. Traditional dividers often involve the extraction of raw materials, leading to deforestation, resource depletion, and greenhouse gas emissions. Recycled options significantly reduce these environmental impacts by diverting materials from landfills and decreasing the demand for virgin resources. This translates into a lower carbon footprint throughout the product lifecycle.

For example, using recycled plastic reduces the need for new plastic production, thereby lessening the strain on oil resources and the associated pollution.

Functionality Evaluation

The functionality of shelf dividers, whether traditional or recycled, depends on the specific design and intended application. Recycled dividers can maintain the same structural integrity and functionality as their traditional counterparts, especially if the recycled material is of high quality and the manufacturing process is robust. However, some recycled materials might have subtle differences in strength or texture, so careful consideration of the specific application is crucial.

For example, a recycled cardboard divider might be suitable for lighter items but not as robust for heavy objects as a traditional plastic divider.

Consumer Motivations for Recycled Products

Consumers increasingly prioritize sustainability and ethical sourcing in their purchasing decisions. Factors such as environmental awareness, a desire to reduce waste, and a commitment to supporting eco-friendly practices drive the demand for recycled products. Consumers are often willing to pay a premium for products that align with their values. This growing trend is creating a dynamic market for innovative and sustainable alternatives to traditional materials.

For instance, the rise of eco-conscious brands and the growing popularity of “buy-less, buy-better” movements further fuel the demand for recycled products.

Potential for Innovation and Design

Recycled shelf dividers, beyond their practical function, offer a rich canvas for innovative design. Their inherent sustainability narrative can be further amplified by pushing the boundaries of form and function. This exploration into potential innovation delves into adaptable designs, customizable systems, and the integration of technology to create truly unique storage solutions.The core principle in innovative design is to leverage the unique properties of recycled materials.

This includes considering the inherent strengths and limitations of the chosen recycled materials, and how they can be manipulated and combined to achieve desired aesthetics and structural integrity. Furthermore, the design should consider the intended use and storage requirements of the consumer.

Innovative Designs for Recycled Shelf Dividers

Recycled materials, particularly plastics and cardboard, can be molded into a variety of shapes and textures. Experimentation with different designs can produce visually appealing and functional dividers. For instance, dividers with integrated handles or built-in organizers can enhance functionality and reduce the need for additional storage accessories. Geometric patterns, embossed textures, or even integrated lighting elements can add aesthetic appeal and make the dividers stand out.

The potential for creating a wide range of visually interesting and practical solutions is significant.

Adaptability to Specific Storage Needs

The adaptability of these dividers is key to their widespread appeal. Dividers can be designed with adjustable heights and widths to accommodate various storage needs. For instance, specialized dividers for storing delicate items or those with specific dimensional requirements, such as electronics or books, are possible. Modular designs can also be employed to create systems that adapt to changing storage needs over time.

By integrating modular components, users can easily reconfigure and rearrange their storage space without significant effort. This is especially valuable for individuals with changing storage demands, such as growing families or evolving businesses.

Customizable and Modular Systems

Customizable and modular systems represent a significant advancement in storage solutions. By offering a variety of interchangeable components, such as different sized dividers, shelves, and accessory holders, users can tailor the system to their specific needs and preferences. This concept allows for a greater degree of personalization and flexibility, surpassing the limitations of traditional, one-size-fits-all storage solutions. The versatility of modular systems will enhance the appeal and value of recycled shelf dividers.

Imagine a system where users can select dividers with specific features, like built-in cable management or adjustable shelving for varying storage needs.

Incorporating Technology into the Dividers

The integration of technology can enhance the functionality and convenience of recycled shelf dividers. Smart dividers could incorporate sensors to track inventory levels or provide alerts when items are running low. For example, light sensors could automatically adjust the lighting in storage areas based on ambient conditions, enhancing visibility and reducing energy consumption. Integration with smart home systems could further streamline storage management and organization.

These advanced features could set recycled shelf dividers apart from traditional alternatives and attract consumers seeking more advanced and intuitive storage solutions.

Final Wrap-Up

Recycled shelf dividers represent a significant shift towards sustainable design in storage solutions. Their cost-effectiveness, combined with a growing awareness of environmental concerns, positions them for substantial market growth. The future likely holds even more innovative designs and applications, further solidifying their place in the evolving landscape of home and office organization.